Panchakanya Group has continuously introduced innovation and modern building

products to the Nepalese market with a promise of strength, safety and speed without any

compromise in quality.

Along with the slogan “switch to smart flooring”, Panchakanya Group has brought Deck

Sheet for easy and speedy construction reducing the load of concrete slab. The deck

sheet is galvanized steel profile with ribs and embossment which helps in gripping

and binding with the concrete slab and together forms a floor structure. These deck

sheets are appropriate and prompt material for the flooring slab with its unique

interlocking system. Decking sheets nowadays has become the most effective method of

constructing floors in steel buildings and has tremendous advantage in high rise building.

| Available thickness-- | 0.8mm |

|---|---|

| Surface Treatment | Coated, Galvanized |

| Zinc Coating | 80 GSM |

| Yield Strength | 286 – 297 |

| Tensile Strength | 345 MPA |

| Finished Width | 2.51 ft. (± 5 mm) |

| Crest depth | 75mm |

| Weight per sq. ft. | 0.81(+-0.05kg) |

| Extensibility | 35 – 40% |

| Fire resistance | 4 Hours |

Time, cost and strength are the most important aspect for the construction.

One of the time-consuming portions of construction is the erection of formwork.

With the use of decking sheet, we can save it all.

In addition to this, considerable amount of concrete and reinforcements can be saved which

not only reduces the cost but also reduces the dead load acting on the structure without

compromising the strength. Reduction of dead load further brings the advantage that the

structure can carry extra loads. Although being light in weight the flooring has good

ability to resist vibration and deflection, thus fulfill the service ability criteria

for design. Also, it is a good insulator of sound and temperature.

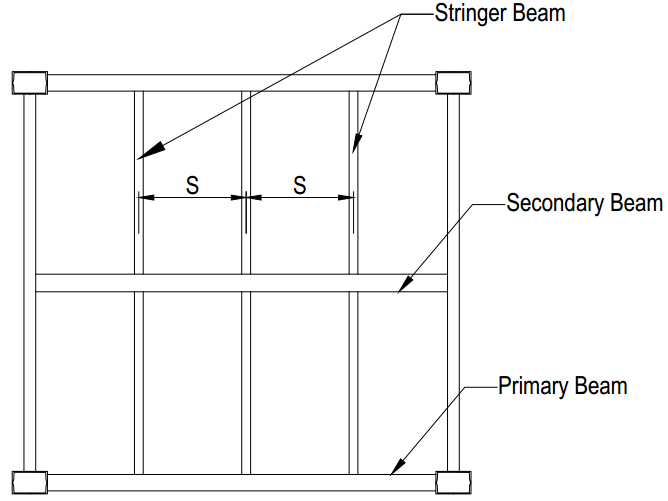

Step 1: Select proper size and spacing of stringer beams supporting the decking sheet.

The spacing ‘S’ depends upon the type of decking sheet

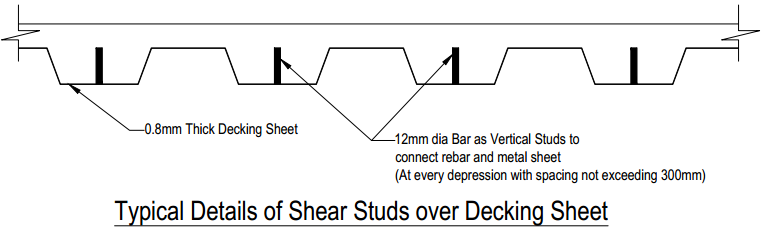

Step 2: Use shear studs above beams at calculated spacing depending upon the type of decking sheet and spacing of stringer beams.

Step 3: Punch hole in decking sheet as per shear stud’s location and lay above stringer beams.

OR

Place the decking sheet over the beams and then weld the shear studs at the designated location using Stud Welder/ Gun.

Step 4: Use shear studs above beams at calculated spacing depending upon the type of decking sheet and spacing of stringer beams.

Step 5: Use temperature and shrinkage mesh at the top face of decking slab with sufficient cover to prevent cracking.

Step 6: Use temperature and shrinkage mesh at the top face of decking slab with sufficient cover to prevent cracking.

To know more about PSS Click here

To know more about CGI Click here

To know more about LGS Click here

My compliments, I commend Panchakanya Steel on the professional and thorough approach it has to delivering and maintain service with us. Thank you for your valuable time and consideration in this respect.

- Mahesh ShresthaThe best company who deliver 100% results. We are thankful to our organization citizens who are our driving force.

- Rajesh Bajracharya